Control Valve Selection Tips for Industrial Applications

Introduction

Control valves are critical components in industrial processes, regulating fluid flow, pressure, temperature, and level in pipelines. Selecting the right control valve ensures system efficiency, safety, and longevity. However, choosing the best valve for a specific application requires careful consideration of multiple factors, including fluid properties, process conditions, valve type, and material compatibility.

This guide provides essential tips for selecting control valves in industrial applications, covering key aspects such as valve types, sizing, materials, actuation methods, and performance considerations.

---

1. Understand the Application Requirements

Before selecting a control valve, engineers must thoroughly analyze the process requirements:

A. Fluid Characteristics

- Type of Fluid: Is the fluid liquid, gas, steam, or slurry?

- Corrosiveness: Does the fluid contain corrosive chemicals?

- Viscosity: High-viscosity fluids may require special trim designs.

- Abrasiveness: Slurries or fluids with suspended solids need abrasion-resistant materials.

- Temperature & Pressure: Extreme conditions may require special materials or designs.

B. Process Conditions

- Flow Rate: Determines the required valve size.

- Pressure Drop: Excessive pressure drop can cause cavitation or flashing.

- Control Rangeability: The valve should maintain control across the full operating range.

- Fail-Safe Position: Should the valve fail open, closed, or in the last position?

---

2. Choose the Right Valve Type

Different control valve designs suit different applications. The most common types include:

A. Globe Valves

- Best for: Precise flow control, high-pressure drop applications.

- Advantages: Good throttling capability, tight shutoff.

- Disadvantages: Higher pressure drop, larger size.

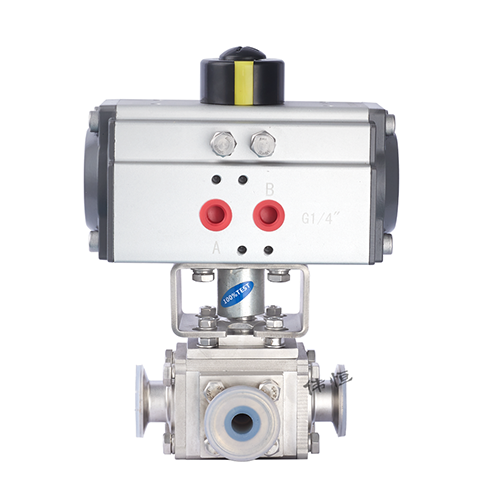

B. Ball Valves

- Best for: On/off or moderate throttling applications.

- Advantages: Low pressure drop, quick operation.

- Disadvantages: Limited fine control compared to globe valves.

C. Butterfly Valves

- Best for: Large flow applications with low-pressure drop.

- Advantages: Compact, lightweight, cost-effective.

- Disadvantages: Limited precision in throttling.

D. Diaphragm Valves

- Best for: Corrosive or slurry applications.

- Advantages: Excellent for handling viscous or abrasive fluids.

- Disadvantages: Limited pressure and temperature range.

E. Plug Valves

- Best for: On/off or moderate throttling in high-pressure systems.

- Advantages: Tight shutoff, durable.

- Disadvantages: Requires high torque for operation.

---

3. Proper Valve Sizing

An incorrectly sized valve can lead to poor control, excessive wear, or system inefficiency. Key considerations include:

A. Flow Coefficient (Cv)

- The Cv value defines the flow capacity of a valve.

- Calculate Cv based on flow rate, pressure drop, and fluid properties.

- Oversized valves cause instability; undersized valves restrict flow.

B. Pressure Drop Considerations

- High pressure drop can cause cavitation (liquid) or choked flow (gas).

- Use anti-cavitation trims or multi-stage designs if needed.

C. Trim Selection

- Standard trim for clean fluids.

- Low-noise or anti-cavitation trim for high-pressure applications.

---

4. Material Selection

Valve materials must withstand process conditions without degrading. Consider:

A. Body & Trim Materials

- Carbon Steel: Good for general-purpose applications.

- Stainless Steel: Resistant to corrosion, suitable for harsh environments.

- Alloy 20, Hastelloy, Titanium: For highly corrosive or high-temperature fluids.

B. Seals & Gaskets

- PTFE (Teflon): Chemical resistance, moderate temperature range.

- EPDM, Viton: For specific chemical compatibility.

C. Coatings & Linings

- Rubber or epoxy linings for abrasive or corrosive fluids.

---

5. Actuation Method

Control valves can be operated manually or automatically. Common actuation methods:

A. Pneumatic Actuators

- Advantages: Fast response, simple design, explosion-proof.

- Disadvantages: Requires compressed air supply.

B. Electric Actuators

- Advantages: Precise control, no air supply needed.

- Disadvantages: Slower response, not ideal for explosive environments.

C. Hydraulic Actuators

- Advantages: High force output, good for large valves.

- Disadvantages: Complex maintenance, potential leaks.

D. Solenoid Valves

- Best for: Small, fast-acting on/off applications.

---

6. Performance & Safety Considerations

A. Leakage Classifications

- ANSI/FCI 70-2 standards define leakage rates (Class I to VI).

- Tight shutoff (Class VI) required for hazardous fluids.

B. Noise & Vibration Control

- High-velocity fluids can cause noise and vibration.

- Use noise-reducing trims or diffusers.

C. Cavitation & Flashing Prevention

- Cavitation occurs when pressure drops below vapor pressure.

- Solutions: Multi-stage trim, hardened materials, or pressure-reducing valves.

D. Redundancy & Fail-Safe Features

- Critical applications may require redundant valves.

- Spring-return actuators ensure fail-safe operation.

---

7. Maintenance & Lifecycle Costs

- Ease of Maintenance: Valves with accessible internals reduce downtime.

- Spare Parts Availability: Standardized designs simplify replacements.

- Total Cost of Ownership (TCO): Consider initial cost, energy efficiency, and maintenance.

---

Conclusion

Selecting the right control valve involves balancing process requirements, valve performance, and cost. Engineers must evaluate fluid properties, operating conditions, material compatibility, and actuation methods to ensure optimal performance. Proper sizing, material selection, and safety considerations help prevent premature failure and improve system reliability.

By following these guidelines, industrial users can enhance process efficiency, reduce downtime, and extend valve service life. Always consult with valve specialists when dealing with complex or high-risk applications.

---

This comprehensive guide provides a structured approach to control valve selection, ensuring safe and efficient operation in industrial settings. Let me know if you need further details on any specific aspect!

টেলিফোন: +৮৬ ৫৭৭ ৮৬৯৯ ৯২৫৭

টেলিফোন: +86 135 8786 5766 /+86 137 32079372

ইমেইল: wzweiheng@163.com

ঠিকানাঃ না। 1633, ইয়াদাওবা রোড, বিনহাই ইন্ডাস্ট্রিয়াল পার্ক, ওয়েনঝো সিটি, ঝেজিয়াং প্রদেশ

স্ক্যান wechat

আপনি আমাদের ওয়েবসাইটে সেরা অভিজ্ঞতা পান তা নিশ্চিত করতে এই ওয়েবসাইটটি কুকিজ ব্যবহার করে।

মন্তব্য করুন

(0)